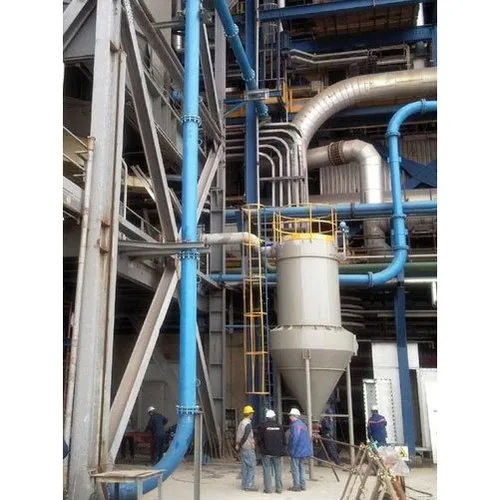

About Pneumatic Conveying System

Pneumatic Conveying Systems / Ash HandlingSystem

Discover UNICONs cutting-edgePneumatic Conveying Systems a dust-free solution that ensures compliance withenvironmental standards. Our dry method eliminates wastewater concerns, makingit ideal for various industries.

Innovativeand Efficient

Experience the future of material handlingwith our state-of-the-art Pneumatic Conveying Systems. Designed for efficiencyand reliability.

- High Efficiency

- Minimal Maintenance

- Versatile Applications

- Environmental Compliance

Advanced Technology for Superior Performance

Our Pneumatic Conveying Systems leveragecutting-edge technology to deliver unparalleled performance. From automatedcontrols to precision engineering, every aspect of our system is designed tomaximize productivity and minimize downtime.

Automated Control Systems

- Precision Engineering

- Customizable Solutions

- Safety Standards

Key Features

-

Economical and Reliable

Cost-effective solution for material handling.

Proven reliability in various industries

Power Efficiency

- Efficient use of energy during conveying.

- Reduces operational costs.

High Capacity Conveying Line

- Handles large volumes of material.

- Ideal for continuous production.

Flexible Control Options

- Most preferable type of control.

- Performs relay logic, timing, counting, and sequencingfunctions.

- Allows customization based on specific needs.

Conveying Distance

- Capable of conveying materials up to 2000 meters.

- Suitable for long-distance applications.

Vessel Sizes

- Wide range of vessel sizes available.

- Tailor the system to your requirements.

Quick Delivery

- Shortest delivery time for system installation.

Troubleshooting and Expansion

- Ability to troubleshoot, modify, and expand the system.

- Adaptableto changing needs.